One of the most primitive examples of roller bearings is a simple set of logs laid along a path for rolling heavy objects. As the object is pulled along the logs, relatively little friction is produced compared with pulling it along a flat surface. Read More…

With a multitude of bearing and slide designs available, both standard and custom designed models, Del-Tron Precision Inc. is proud to be a one-stop shopping experience for customers with linear motion needs.

TUSK Direct is a company that produces high quality linear motion components such as linear bearings as well as assemblies for automated equipment.

Isotech is a distributor of precision linear motion components -- crossed roller linear bearings, ball slide assemblies, crossed roller slide tables, motorized tables, position stages and more.

At Hartford Technologies, we take pride in our commitment to precision engineering and cutting-edge technology, positioning ourselves as a leading provider of linear bearings. With a rich history rooted in excellence, we have consistently pushed the boundaries of what's possible, delivering high-performance linear bearings that cater to diverse industrial needs.

More Linear Roller Bearing Manufacturers

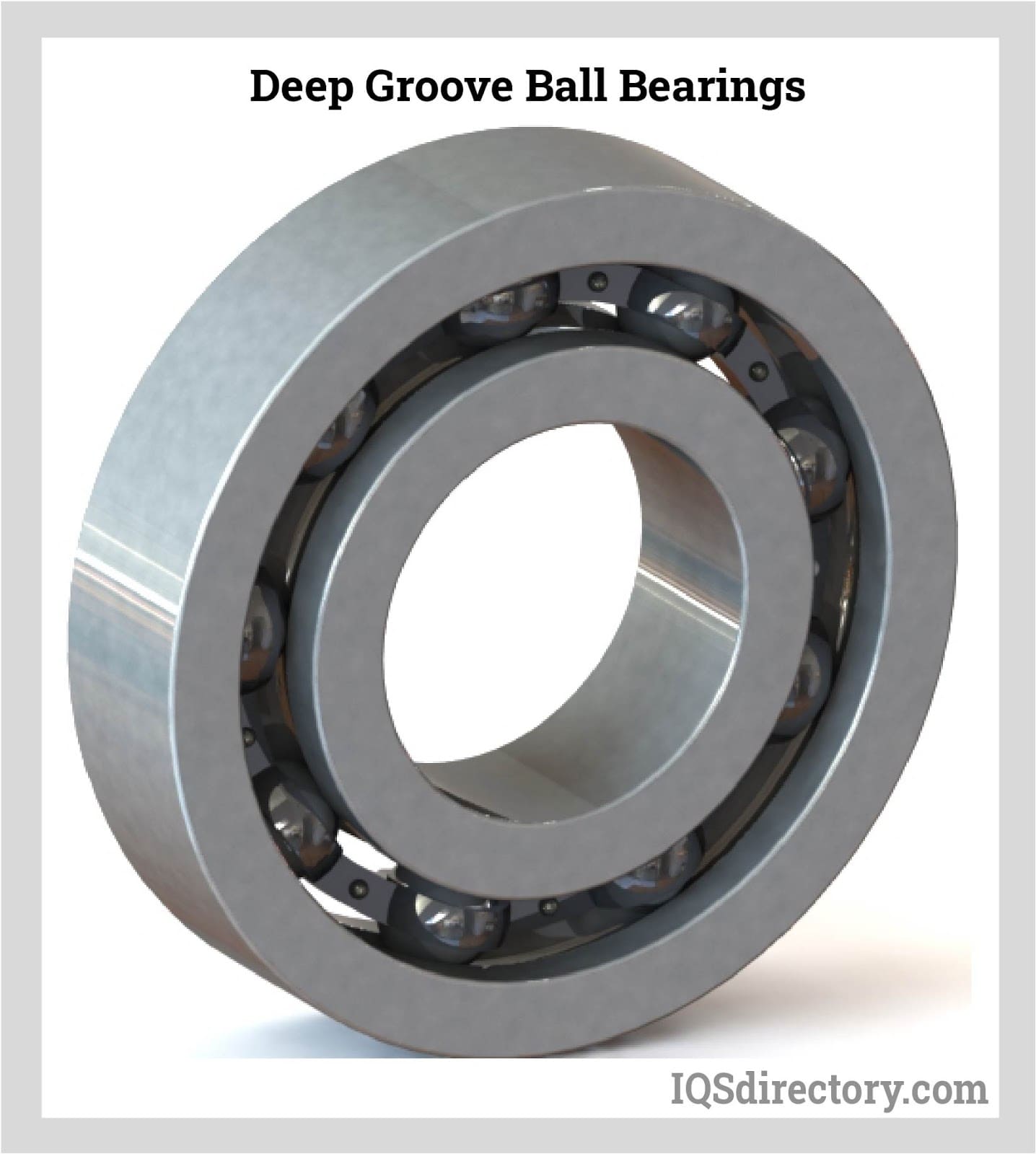

Modern roller bearings operate on the same principles and roller bearings work similarly to ball bearing slides except that the bearings in the carriage are cylinder shaped rather than spherical. In these precision linear bearings, the rollers themselves are kept in place by sitting between v-shaped grooves of the top carriage and base. The stationary base provides the surface for the load to move across and the mobile carriage is able to bear the load to its desired position.

Linear rolling bearings are able to carry heavy loads and still provide low-friction motion. Roller slides tend to be a longer lasting option than ball slides as they distribute the weight of a load along the length of the cylinder, rather than on the point of a sphere, therefore resulting in less surface contact under pressure and less deterioration.

They are a relatively cheap motion device and are easy to manufacture and put into place. Linear motion bearings are used in a wide variety of applications. Industries such as manufacturing, consumer, medical and telecommunications all use roller bearings to aid in processing and operations. Aluminum and stainless steel are the materials commonly used to manufacture roller slide systems as they are durable metals which are able to withstand both the weight of loads and the wear and tear of motion.

Roller systems can be adjusted according to specific application requirements, and the addition of components such as support rails or guide wheels can further ensure the smooth linear motion. Some systems may include covers or bellows to protect against dirt and dust entering the shaft assembly, as well as rail wipers to clean the rails before the rollers are moved over them. Motion locks can also be used to slow or stop linear motion, or to hold a carriage position for a period of time.

The systems will require periodical maintenance however, especially in applications where airborne debris or corrosion may be a factor and with miniature linear bearings. To ensure the smoothest motion possible within the system, the assemblies may have to be opened and cleaned from time to time, as well used with a lubricating substance of sorts.

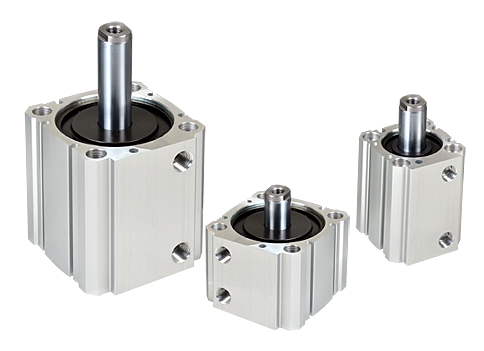

Air Cylinders

Air Cylinders Assembly Machinery

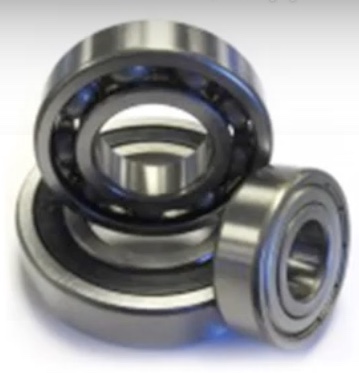

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services